Ground Source Heat Pump (GSHP)

Also known as a Geothermal Heat Pump. Standard heat pumps rely on outside air as a heat sink or source. A ground source heat pump uses the stable temperature of the earth as the source or sink. This allows them to operate much more efficiently. Our system has one 220' shaft per ton of capacity.

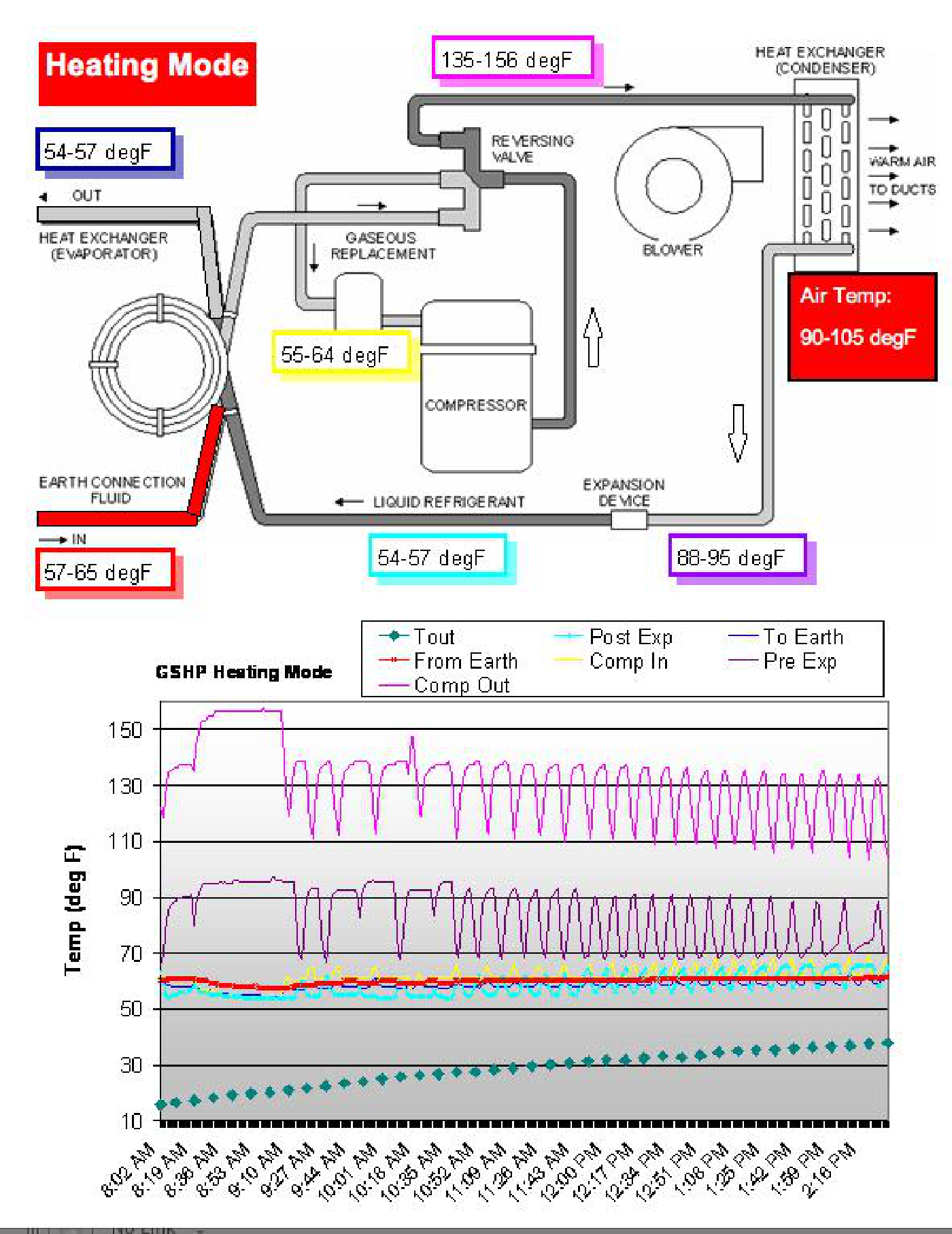

In the summer, the condenser is rejecting heat to the 70 deg F earth instead of the 100+ deg F air. In the winter the unit draws heat from the 70 deg F earth instead of the cold outdoor air. In the winter, the warm water is pulled from the earth then passed through the compressor where it is warmed enough to reject heat into the house. The data on the graphic shows the unit in heating mode.

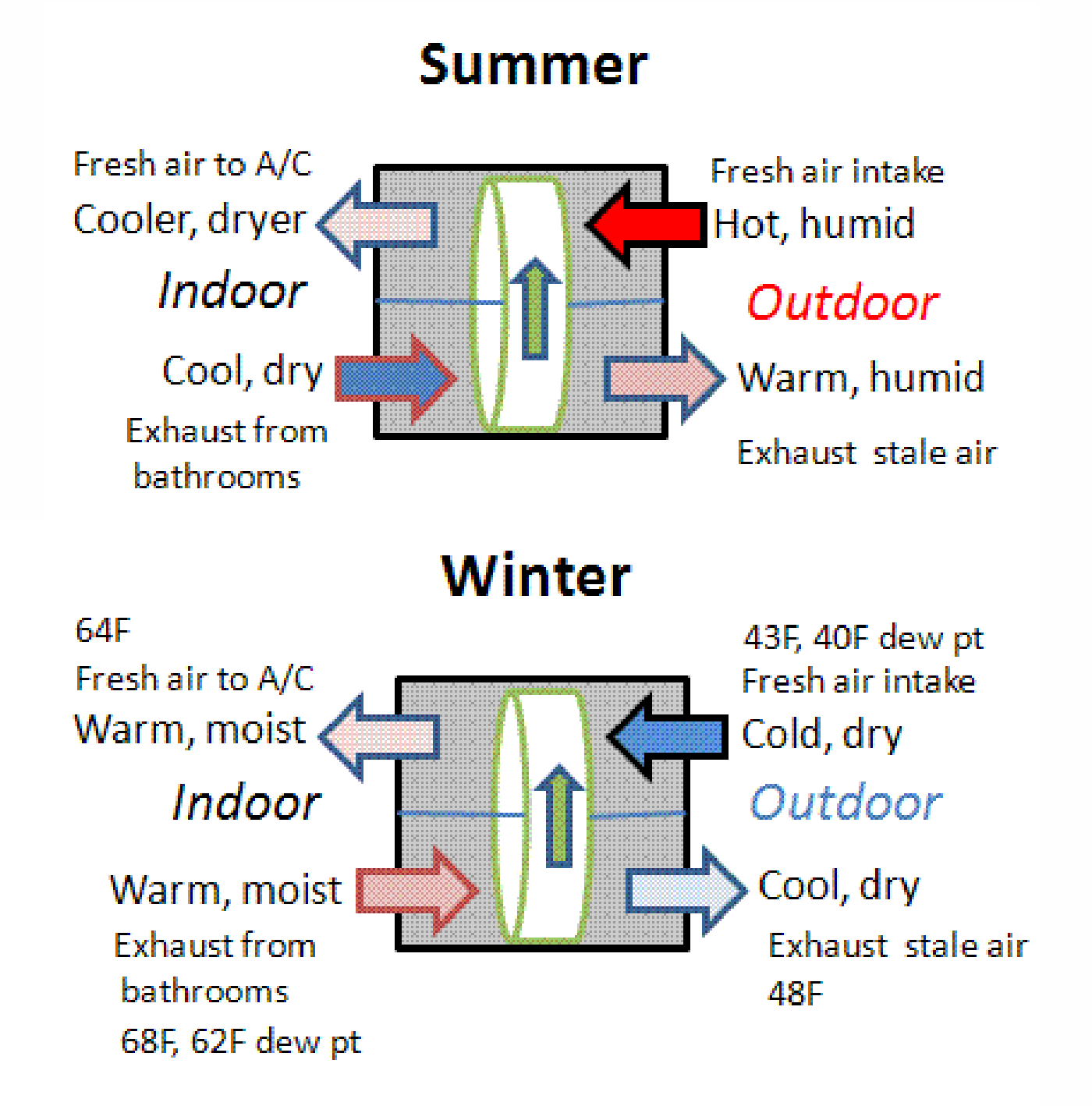

Our unit is a 2-speed system to better match the variable load. In runs most of the time in low speed mode which allows it to better dehumidify the air in the summer, which makes the house more comfortable. Running longer in low speed is more effective and efficient than running for shorter bursts in high speed.

The first step is always to build a good shell - well insulated with minimal infiltration. The is will reduce the size of the heating and cooling system. Here's a link with more details and information about how geothermal heat pumps work.